LDIR Imaging

LDIR Chemical Imaging Spectroscopy

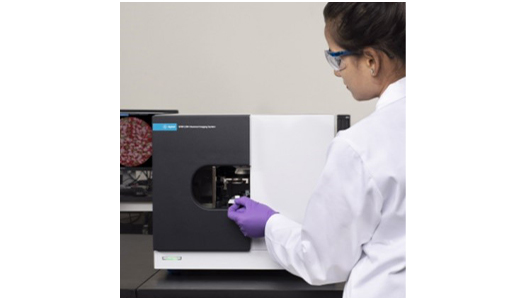

The Agilent 8700 Laser Direct Infrared (LDIR) provides a sophisticated new approach to chemical imaging and infrared spectral analysis. Designed to be used by experts and nonexperts alike, the 8700 LDIR provides a simple, highly automated approach for obtaining reliable high-definition chemical images of constituents on surfaces.

Using the 8700 LDIR, you can analyze more samples, in greater detail, in minutes vs. hours. With automated workflows for pharmaceutical tablets and microplastics in environmental samples, as well as capabilities for analyzing tissues, laminates, polymers, and fibers, the 8700 can help you make better, faster decisions in product development, reducing costs and

Request Info/Quote

Features

- Enables expert spectroscopists and trained technicians to analyze and characterize samples rapidly and accurately

- Highly automated workflow for characterizing surface distribution of components in pharmaceutical tablets

- Automated chemical imaging workflow for microplastics in environmental samples and drinking water

- Ability to survey and image large sample areas and then interrogate smaller areas of interest in more detail without changing any optics

- Full control using Agilent Clarity software

- Change the field of view from microns to centimeters or the pixel size from 1 to 40 µm, and acquire ATR imaging data with pixel size as small as 0.1 μm for unmatched image detail and spectral quality

- Rapidly identify unknowns using either commercial or custom libraries via ATR capabilities

- Obtain relative quantitative information of sample constituents without complex method development

- Quantum cascade laser (QCL) and thermoelectrically cooled detectors eliminate the need for liquid nitrogen, reducing operating costs and simplifying maintenance

- Simple load-and-go methods require minimal instrument interaction, and small footprint saves laboratory bench space

LDIR Technology for Microplastics Analysis

Laser direct infrared imaging (LDIR) is a new technique for IR spectroscopy. It combines a tunable quantum cascade laser (QCL) as the IR source with rapidly scanning optics. It can be used in two modes: frequency parked with rapid scanning over a large area, or position parked with rapid sweep through the entire available wavelength range with resolution at the diffraction limit. LDIR detects microplastic particles by rapid imaging of the area using IR light rather than visible cameras to determine the location, size, and shape of particles. Spectra can then be obtained from individual particles and compared to the onboard library, with results presented in real time.

LDIR overcomes some of the key limitations of FTIR systems such as eliminating the need to collect data in empty spaces. This results in significantly faster analysis times and it can also be fully automated. A QCL operates at lower power than lasers used in Raman, hence fluorescence and sample damage pose no risk. An electrically cooled detector eliminates the need for liquid nitrogen, yet it has the highest resolution of any IR system and can detect particles as small as 10 µm. It is, however, relatively new technology. This, coupled with the use of the fingerprint region of the IR spectrum, only means that relevant libraries of data are less developed than other systems.

Advantages

- A new approach to IR spectroscopy and is therefore well understood and accepted

- Highly automated and fully integrated workflow; no need for external data processing

- Fast, especially compared to FTIR where the quantum cascade laser allows us to scan the area for particle location using IR rather than visual light for particle detection

- Fast, as we can obtain particle spectra much faster than FTIR (1 second compared to 30 seconds)

العربية

العربية